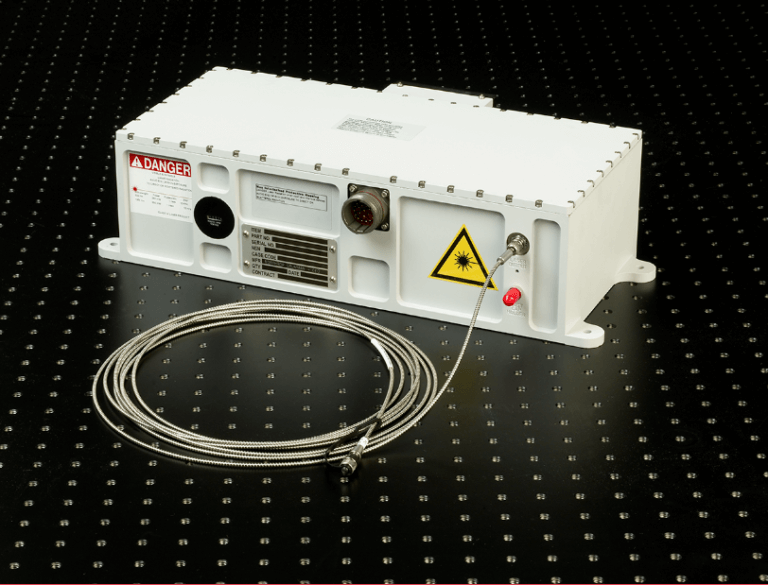

Cutting Edge Optronics, a subsidiary of Northrop Grumman, has extensive experience developing and manufacturing military and aerospace solid state laser systems. Applications for these systems include LIDAR, bathymetry, satellite tracking, illumination, imaging, non-destructive testing, aircraft paint stripping, and nuclear fuel enrichment. Many of these applications are airborne in nature and often operate in harsh environments. Environmental stress screening (ESS) plays a key role in validating these systems prior to deployment. CEO recently completed ESS re-qualification testing after pre-planned engineering updates to one such laser system, the Airborne Laser Mine Detection System (ALMDS) Laser.

Figure 1 – The ALMDS laser system is shown mounted on a MH-60S helicopter (https://www.northropgrumman.com/what-we-do/air/airborne-laser-mine-detection-system/).

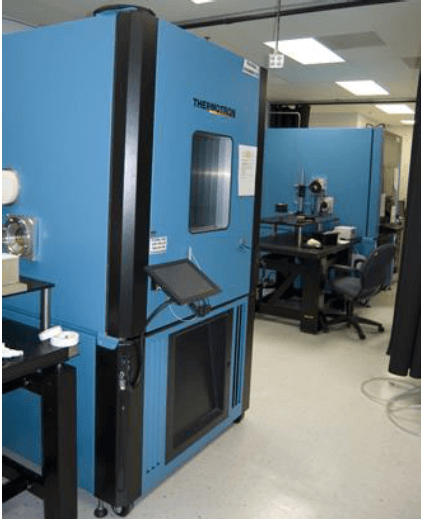

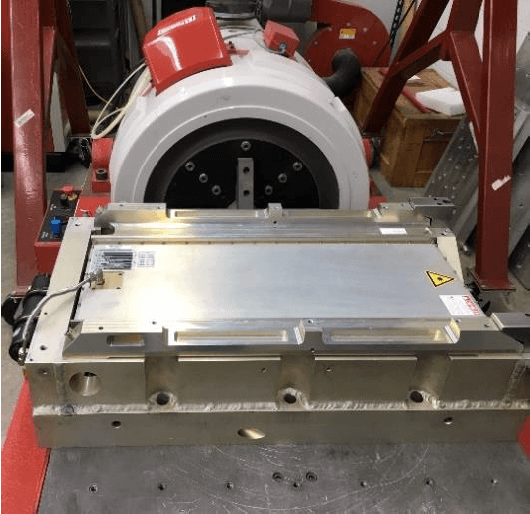

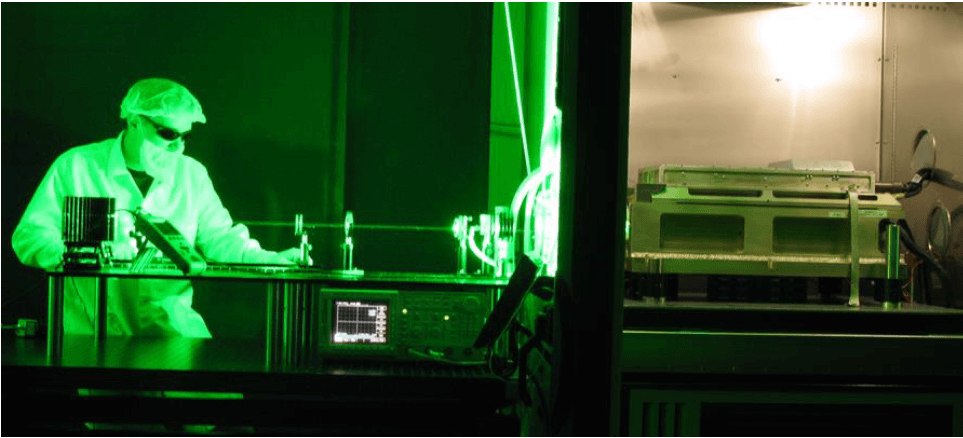

The ALMDS laser is a well-established system that has been flight qualified on multiple airborne platforms. The laser’s design was recently updated to allow one of the components to be replaced with a more optimal model. MIL-STD-810F thermal, vibration and shock testing was completed at CEO on a representative laser following the design modifications. The laser’s performance parameters were measured before and after each environmental exposure. Design, manufacturing, optical testing and environmental testing were all completed at CEO’s facility in St. Charles, MO. “The capability to complete ESS testing in-house allows CEO to minimize the duration and cost of the design, manufacturing and qualification processes” said Jeremy Junghans, Senior Engineer.

…

Figure 3 – An ALMDS laser system is shown during operational thermal testing (external chamber left; internal chamber right).

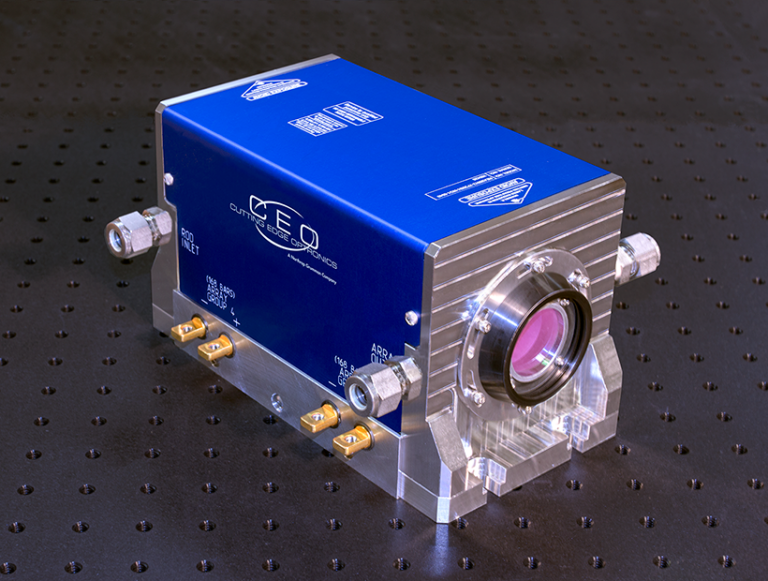

Additional information about CEO is below:

– CEO is experienced with the design, development and manufacturing of DPSS lasers for airborne LIDAR.

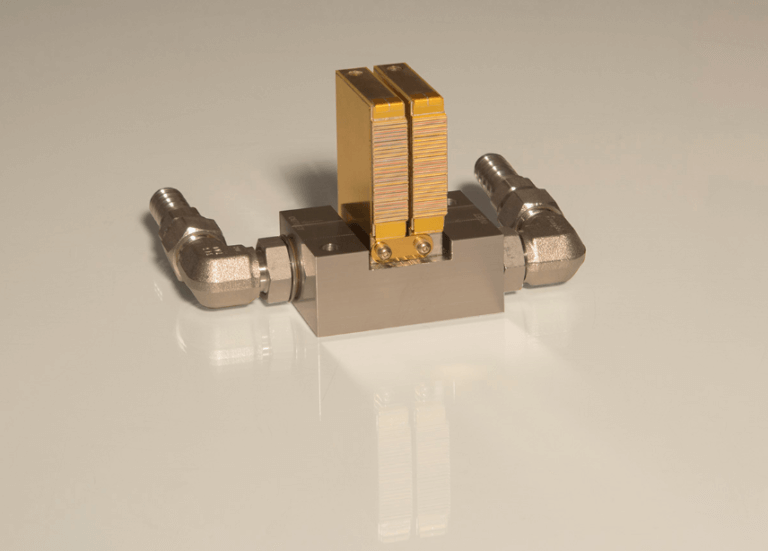

– CEO also provides Laser Diode Arrays specifically designed for high-temperature operation.

In addition to above products, CEO also provides High-Volume, Customer-Specific Diode Arrays to many OEM customers.

Approved for Public Release: NG20-2465 © 2020, Northrop Grumman.

Cutting Edge Optronics Inc