6 Joule Nd:YLF Laser Amplifier

Cutting Edge Optronics (CEO Laser) recently manufactured the largest, commercially available, diode pumped Nd:YLF laser amplifier in the world. This PowerPULSE series laser amplifier pumps a one inch Nd:YLF laser rod with more than 150 QCW laser diode bars, and produces more than 5 Joules of gain switched energy and over 6 Joules of stored energy.

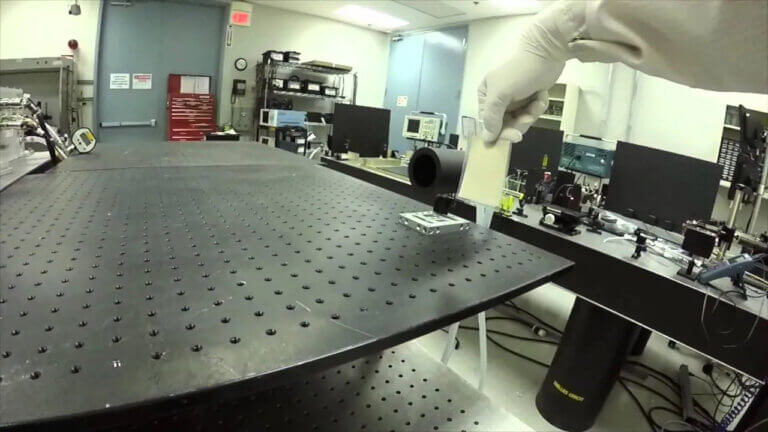

Custom Laser Manufacturing (video)

Cutting Edge Optronics specializes in custom DPSS laser manufacturing for the commercial, industrial, and military / aerospace markets.

STEM Student Open House

Cutting Edge Optronics (NG-CEO) recently hosted a Science, Technology, Engineering and Math (STEM) student open house for 21 middle and high school students. The students participated in a day full of fun activities, facility tours and lectures. The students played games that taught them some basics of laser alignment and mechanical tube bending. The facility tour also included a demonstration of laser engraving. The students had the opportunity to observe the laser engraving process, and each was given a personalized flash drive with their name inscribed.

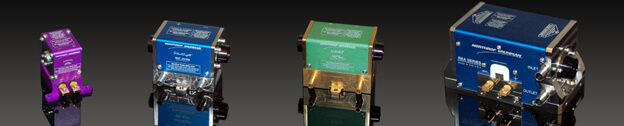

Laser Drive Electronics

Laser drive electronics are a very important consideration when designing any DPSS laser system. Controlling multiple laser system functions and managing the operational and safety interlocks are critical requirements.

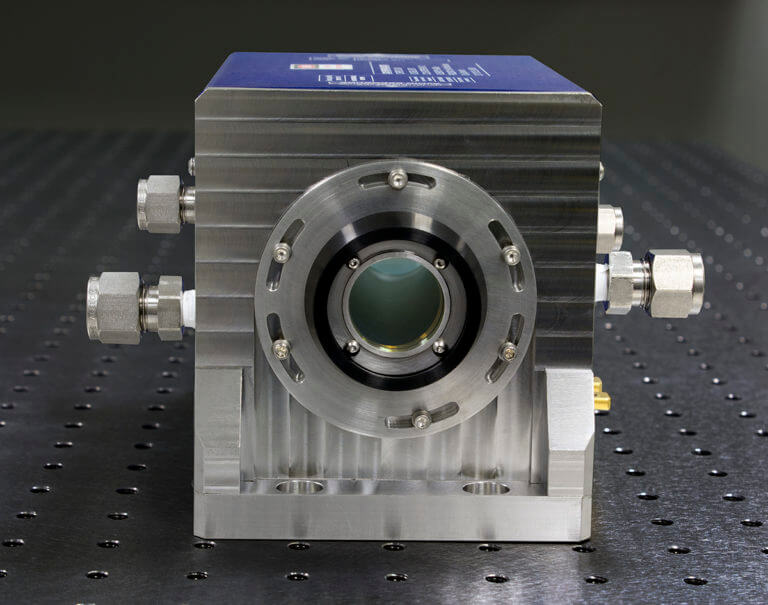

Record Demand for CEO Laser Amplifiers

Cutting Edge Optronics (CEO) recently manufactured one of the largest commercially available diode pumped laser amplifiers in the world. The laser amplifier pumps a one inch diameter Nd:YAG laser rod with more than 400 QCW laser diode bars, and produces more than 9 Joules of gain-switched energy and over 7.5 Joules of stored energy. This is one example of several large laser amplifiers CEO has manufactured over the past 12 months. In order to keep up with the record demand level for laser amplifiers, CEO has doubled its manufacturing capability in 2014.

7.5 Joule Laser Amplifier

Cutting Edge Optronics (CEO Laser) recently manufactured one of the largest, commercially available, diode pumped laser amplifiers in the world. This REA Series laser amplifier pumps a one inch diameter Nd:YAG laser rod with more than 400 QCW laser diode bars, and produces more than 9 Joules of gain switched energy and over 7.5 Joules of stored energy.

Time-Resolved SRS Laser Spectroscopy

Dr. Jun Kojima of the Ohio Aerospace Institute with Dr. David Fischer and Dr. Quang-Viet Nguyen of the NASA Glenn Research Center recently tested a new architecture for SRS laser spectroscopy to realize time-resolved combustion diagnostics.

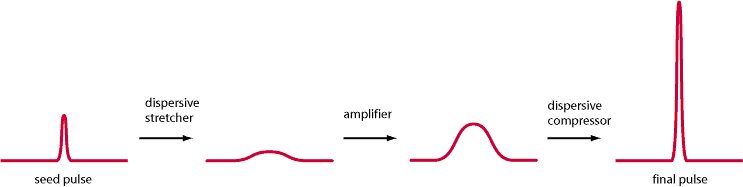

Ti:Sapphire Laser Overview

Ti:Sapphire lasers have become prominent in the field of ultrafast lasers and oscillators due to their broad emission bandwidth and the ability to minimize opto-thermal effects over a wide range of operating parameters. This article examines the construction of a high-power Ti:Sapphire laser from the ground up. Mode-locked lasers are discussed, as are single-pass, multi-pass, and regenerative amplifiers. The use of pulse pickers to help generate higher pulse energies is also discussed.

In order to build high-average-power Ti:Sapphire lasers, high-quality high-average-power green pump lasers are required as pumps for the final amplification stage. This article examines the main requirements on the pump lasers, and also discusses the relative merits of Nd:YAG and Nd:YLF systems.

Pump Lasers for Ultrafast Amplifiers

Ti:sapphire lasers have become prominent in the field of ultrafast lasers and oscillators due to their broad emission bandwidth and the ability to minimize opto-thermal effects over a wide range of operating parameters. In order to build high-average-power Ti:sapphire lasers, high-quality high-average-power green pump lasers are required.

Cutting Edge Optronics (CEO) offers the Patara-HP family of Q-switched green lasers, which are ideally suited as pump sources for pulsed Ti:sapphire amplifiers. The performance of the Patara-HP pump lasers is examined in this work, particularly the 100W and 200W average power systems. An analysis of pulse energies at varying repetition rates, beam quality and stability, pulse-to-pulse stability, long-term power stability and beam pointing stability is presented. A discussion of laser system reliability is also included.