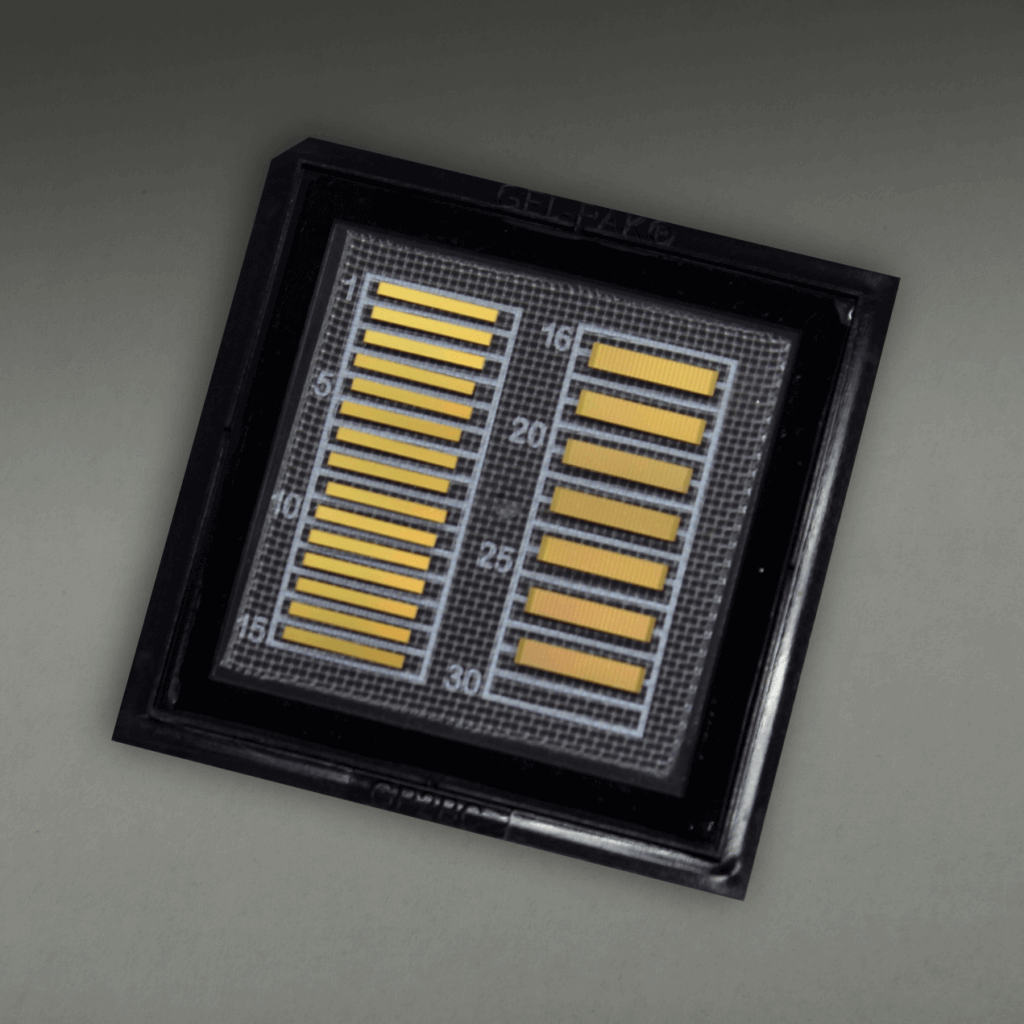

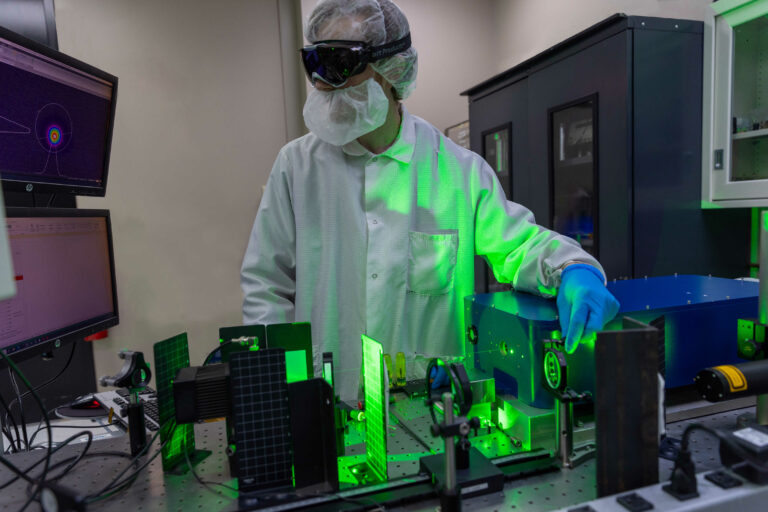

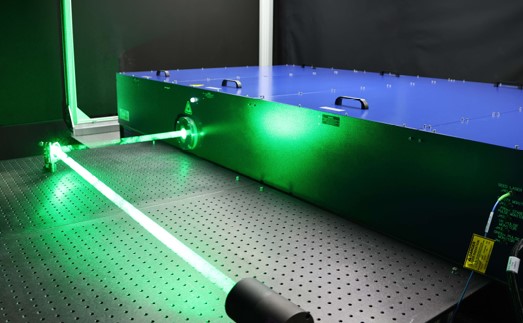

The RBAT and REA series diode-pumped solid-state (DPSS) gain modules from Cutting Edge Optronics serve as central building blocks for high energy, high repetition rate burst-mode laser systems. Burst-mode laser systems achieve high pulse energy in combination with high repetition rate operation by grouping a series of closely spaced pulses into short bursts, thereby reducing the overall average system power. Diode pumping enables burst durations on the order of 100 ms, in contrast to flashlamp-pumped systems, which are limited to about 10 ms bursts. Repetition rates within the burst can be tunable from a single pulse to 1MHz with flexible pulse durations. A sequence of RBAT and REA modules with rod sizes ranging from 2 mm to 32 mm, along with Cutting Edge Optronics’ eDrive laser diode drive electronics, are key components in producing bursts with better than 1% burst-to-burst stability and better than 2% pulse-to-pulse stability within the burst. A long pulse burst-mode laser system provides an alternative to continuously pulsed and CW lasers in applications such as flow diagnostics and other scientific research.

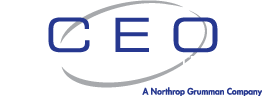

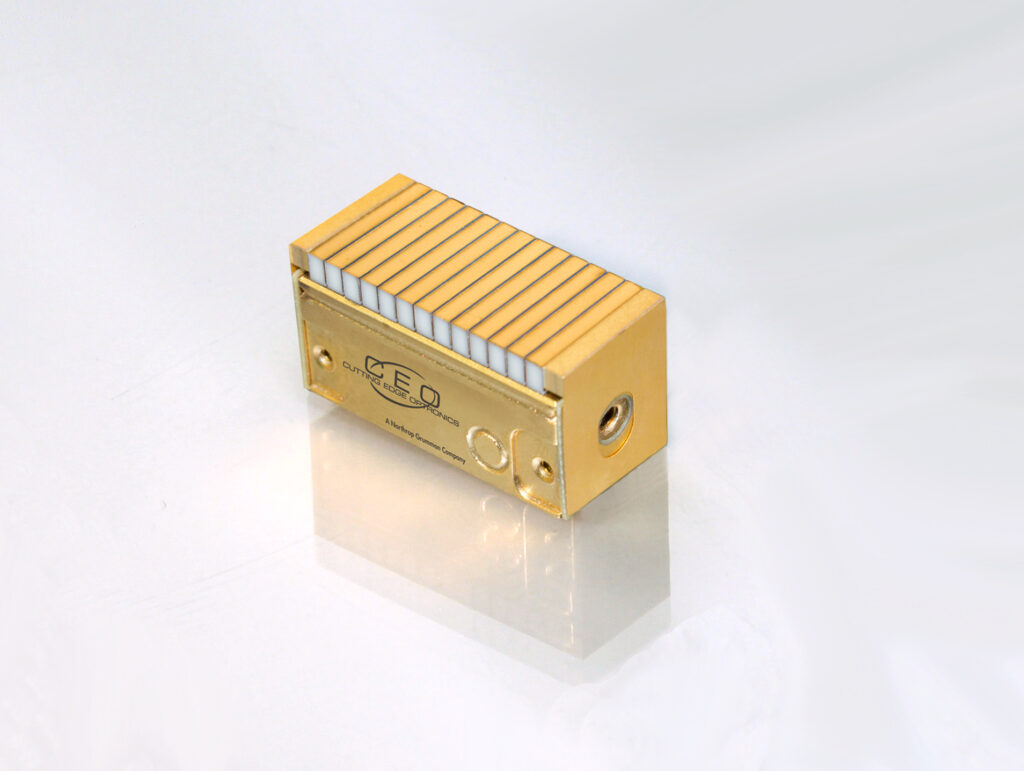

RBAT Modules – Compact, Flexible Gain Modules

- The RBAT series offers rod diameters from 2 mm to 4.5 mm, using standard gain media such as Nd:YAG or Nd:YLF.

- These modules can operate under continuous wave (CW) or quasi-continuous wave (QCW) pumping.

- In practical systems, RBAT modules support CW output powers up to approximately 150 W and long-pulse energies around 500 mJ.

- Because of their small size and flexibility, RBAT modules are suitable as the master oscillator or initial amplifier stage in diode-pumped MOPA (master-oscillator power amplification) systems, especially those intended for pulsed, burst-mode or Q-switched operation.

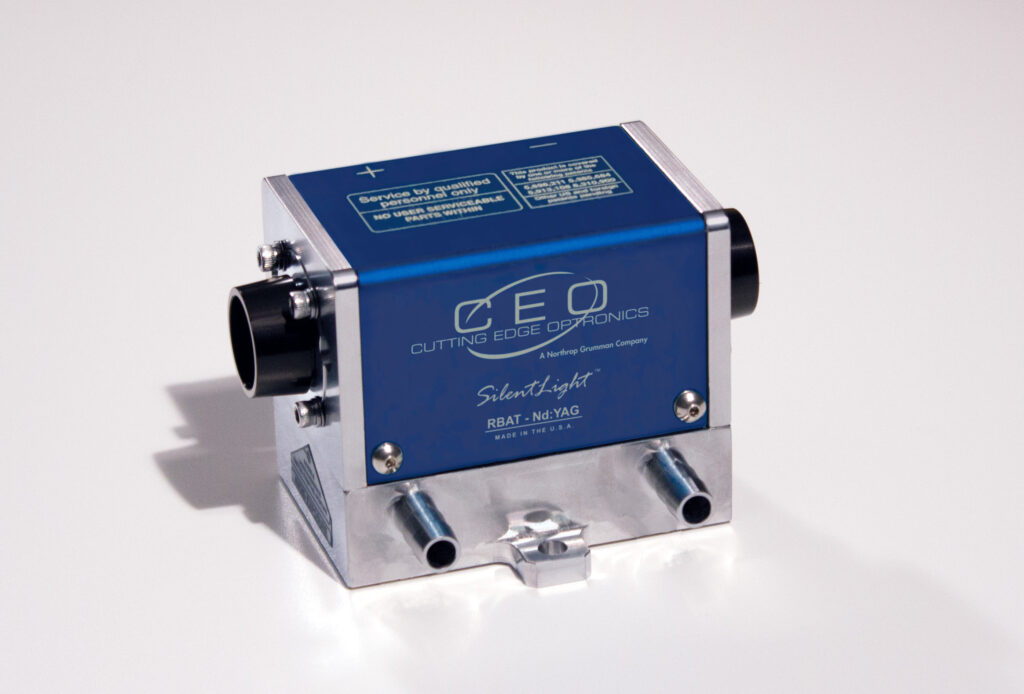

REA Modules – High Energy, High-Capacity Amplifiers

- The REA series supports larger rod diameters (from 4 mm up to 32 mm), allowing much higher stored energy, which is a critical factor for achieving high output energies.

- Under CW operation, REA modules can deliver output powers up to approximately 650 W.

- For pulsed or burst-mode operation, they can provide high pulse energies – making them well-suited for amplifying seed pulses from oscillators to the energy levels required for demanding applications in both single-pass or multi-pass configurations.

- REA modules can be configured as QCW diode-pumped amplifiers in nanosecond MOPA laser systems or used in unstable resonator designs for high peak energy and high average power applications.

Why Cutting Edges Optronics’ RBAT + REA Architecture Works Well for Burst-Mode / QCW Lasers

- Operating amplifiers in quasi-CW (QCW) or burst-pumped regimes allows the modules to handle high pump powers intermittently, avoiding the thermal loading and gain medium stress that continuous high-power pumping can cause.

- The modularity – smaller RBAT stages for seeding/oscillation, larger REA stages for amplification, and eDrive laser diode drive electronics for tailored pulse duration – provides flexibility to tailor each laser’s output parameters (pulse energy, burst duration, repetition rate) to specific application requirements.

To explore available RBAT and REA configurations and related drive electronics, visit our laser gain modules catalog.

Approved for Public Release: NG25-2258. © 2026 Cutting Edge Optronics, Inc.