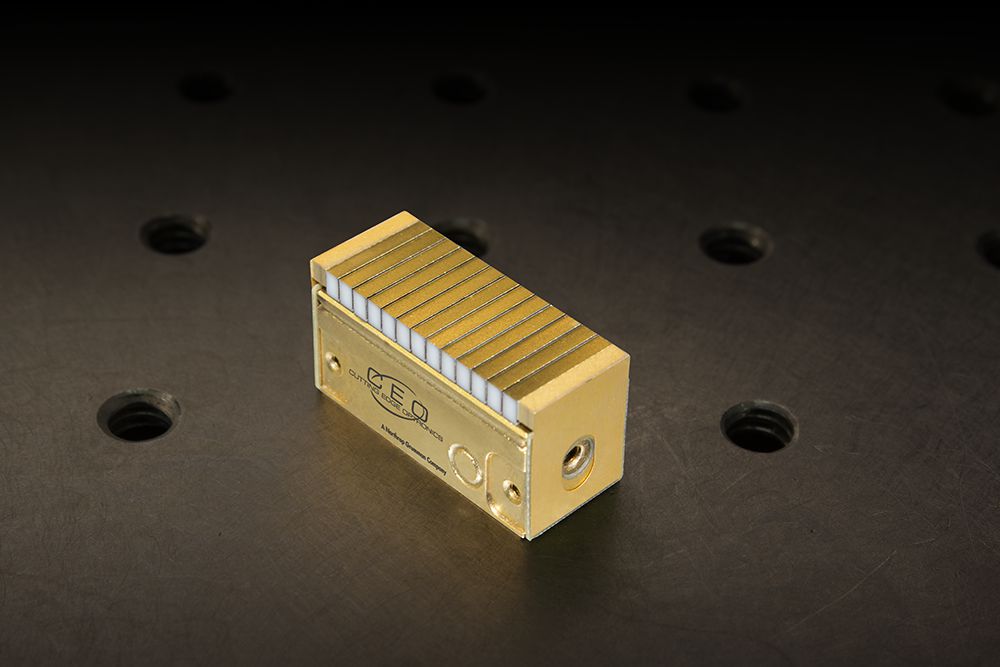

Cutting Edge Optronics (CEO) leverages automated bonders in its automation center to increase capacity and improve quality across many of its product lines. These bonders are routinely employed to build subassemblies with one or multiple diode bars which are then incorporated into CEO’s diode arrays, laser amplifiers, and DPSS lasers.

According to Jeremy Junghans, CEO’s Engineering Manager for Laser Diode Production, “We have developed a wide range of die attach processes utilizing gold-tin (AuSn) solder and various CTE-matched heatsinks. We apply these processes to build subassemblies that are used in numerous applications across our customer base.”

The bonders are operated on multiple shifts, nearly around the clock, which facilitates the manufacture of high-volume products. One of the products that makes extensive use of the automated bonders is the H-package, shown below. These arrays feature full-hard-solder construction and are commonly used in long (> 50ms) pulse applications, such as hair removal.

Approved for Public Release: NG23-0038 © 2023, Northrop Grumman.