In the captivating world of diamond cutting, precision and finesse reign supreme. The transformation of rough stones into dazzling gemstones requires cutting-edge technology that can bring out the true

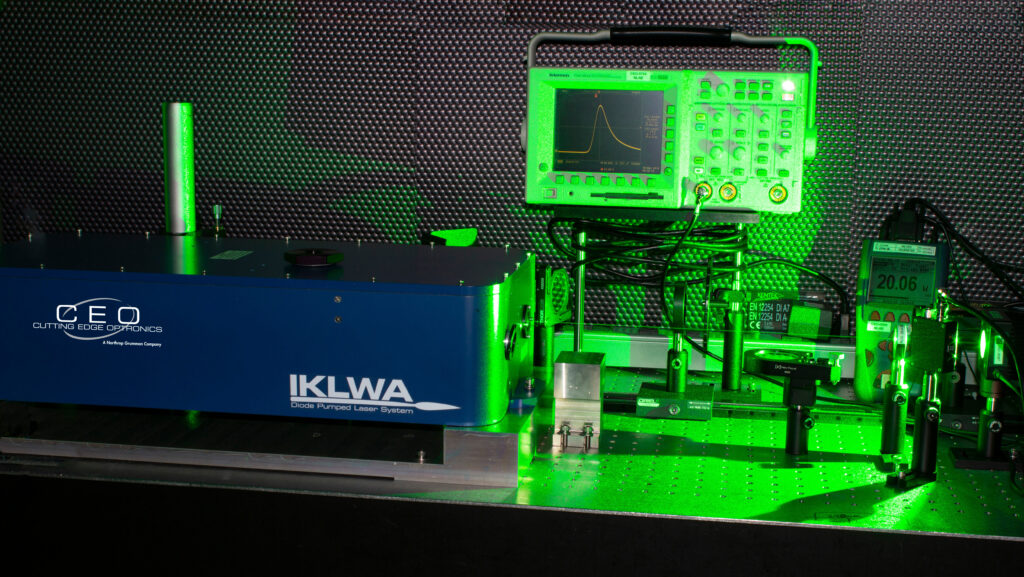

brilliance and beauty hidden within. At Cutting Edge Optronics (CEO), we have harnessed the power of advanced laser technology to help revolutionize the diamond cutting process. Our state-of-the-art Iklwa/Patara lasers set new standards of excellence in diamond cutting machines, offering unparalleled performance and elevating diamond cutting capabilities to unprecedented heights.

At CEO, we recognize the intricate artistry, science and technology behind diamond cutting. With our pioneering Iklwa/Patara lasers, we have unlocked new possibilities and pushed the boundaries of precision. Powered by innovative design and manufacturing technologies, our lasers offer exceptional control and accuracy, enabling diamond cutting machine manufacturers to achieve remarkable results that were once deemed unattainable. At the heart of each laser resides CEO’s advanced SilentLight DPSS laser module, ensuring superior beam pointing and pulse to pulse stability as well as a nearly perfectly round beam shape at focus, allowing for precise material removal without damaging the surrounding areas. With our lasers installed in their machines, diamond cutters can achieve the ideal symmetry, proportions, and facets that bring out the mesmerizing brilliance of each stone.

CEO has been at the forefront of laser technology advancements for years. Our commitment to continuous innovation and research has allowed us to develop laser systems specifically tailored for diamond cutting, of both traditionally mined as well as new, synthetically grown crystals. Paying attention to the 24/7/365 operational requirements of the diamond cutting business, our Iklwa/Patara lasers set the standard of excellence in the industry for performance, reliability and lifetime, empowering diamond cutters to create extraordinary gems that capture the hearts and imaginations of admirers worldwide.

All Iklwa/Patara laser modules are pumped with CEO’s own laser diode arrays – designed and manufactured in the same factory as the laser systems themselves – ensuring optimal performance and efficiency. The lasers are designed for easy serviceability with straightforward laser diode replacement once end of life (EOL) has been reached after years of operation in diamond cutting factories.

As the world of diamond cutting evolves, CEO remains dedicated to pushing the boundaries of what is possible. Our state-of-the-art Iklwa/Patara lasers offer unparalleled precision and finesse, elevating the diamond cutting experience to extraordinary levels. By choosing CEO’s lasers, diamond cutting machine makers gain access to revolutionary tools that unlock new realms of creativity and enable the creation of truly exceptional diamond masterpieces. Join us in embracing the power of laser technology and witness the transformation of rough stones into dazzling works of art.

Approved for Public Release: NG23-0038 © 2023, Northrop Grumman.