Cutting Edge Optronics (CEO) offers a complete DPSS laser platform dedicated to the scientific field of particle image velocimetry (PIV). With a rich history of supporting scientific and industrial applications, CEO produces one of the highest energy per pulse PIV lasers (50mJ @ 1 kHz) available on the market today. Leveraging off of their field-proven industrial platform (Patara-HP), CEO has merged this dual oscillator laser with field tested technology to produce a high performing / rock solid laser solution to meet the ever growing needs of flow visualization.

“Packaging this system into our existing Patara-HP™ laser platform builds on years of success with 100’s of fielded lasers” says Donna Berns, Technical Sales Manager, Cutting Edge Optronics. “We now produce a robust and reliable laser with some of the highest pulse energies available at 1 kHz and perhaps the best beam quality available on the market. This is an exciting product family in terms of scalability, flexibility and performance. We are excited to offer the education and research community a very competitive laser solution for flow visualization.”

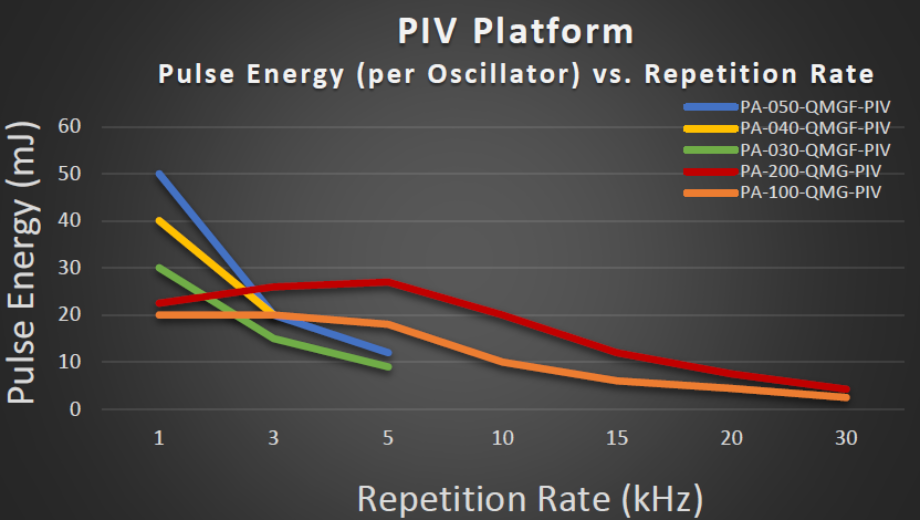

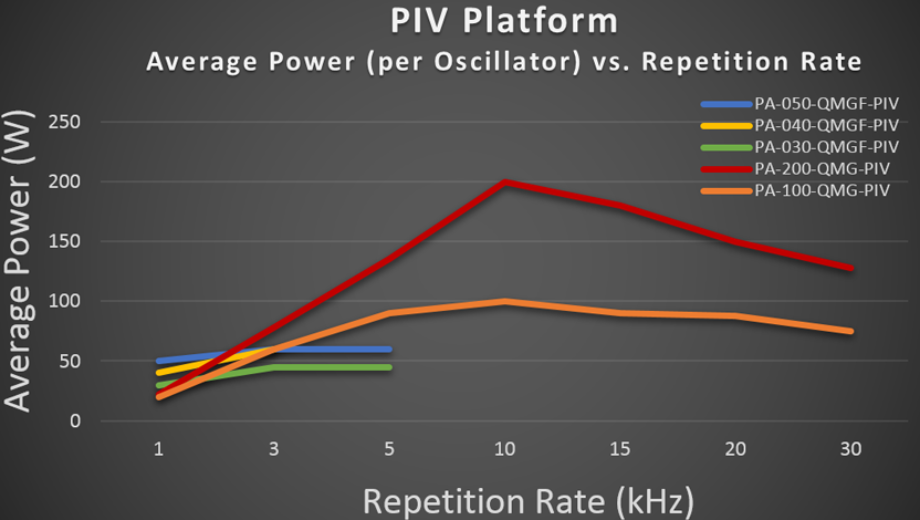

Tracking high speed particles to obtain instantaneous velocity measurements in fluids and gases requires short exposure time and an illuminating laser light sheet with short pulse widths and high pulse energies. In high speed PIV applications, high frequency lasers are required to maintain synchronization with modern cameras utilizing CCD sensors. “This family of PIV lasers covers a wide range of output energies and repetition rates that meets or exceeds many current requirements established by educational and research PIV applications.” Berns continues. “However, development of our 50 mJ system pushes the limits with what is available on the market today and creates new possibilities for researchers world-wide.”

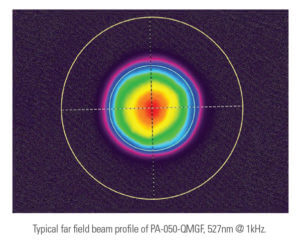

This flexibility offers the end user the ability to select the proper laser to visualize flow dynamics with excellent output beams that are temporally and spatially uniform and stable. Each laser’s optimized beam profile generates homogenous far field light sheets that offer nearly identical shot-to-shot illumination.

| Model | Average Power* | Energy Per Pulse* | Rep Rate Range |

|---|---|---|---|

| PA-100-QMG-PIV | 100 W | 10 mJ | 1kHz – 30kHz |

| PA-200-QMG-PIV | 200 W | 20 mJ | 1kHz – 30kHz |

| PA-030-QMGF-PIV | 30 W | 30 mJ | Single Shot – 5kHz |

| PA-040-QMGF-PIV | 40 W | 40 mJ | Single Shot – 5kHz |

| PA-050-QMGF-PIV | 50 W | 50 mJ | Single Shot – 5kHz |

*At specified repetition rate

The history of the Patara™ DPSS laser dates back to its introduction into the diamond processing industry in 2006. The 1st generation was designed specifically for micromachining applications and produced 16W @ 532nm, TEMoo. Since the initial production units were delivered, 100’s of units have been installed world-wide and the platform has grown in several iterations to support a variety of scientific and industrial applications including ultrafast amplifier pumping and paint stripping.

With 25 years of DPSS laser manufacturing experience, CEO is one of the last vertically integrated manufacturers in the industry. The entire manufacturing process takes place under a single 36,000 ft² roof located in St. Charles, Missouri. CEO’s vertical business model and experienced workforce gives them intimate knowledge and flexibility with every product that is utilized in the manufacturing process.

“We manufacture virtually every component within our laser systems” adds Berns. “From laser diodes, laser diode arrays, gain modules to electronics, you cannot walk 100 steps within our facility without interacting with an expert in the process. It’s this unique culture that allows us to leverage our past experiences into future successes.”

Approved for Public Release 17-1146

© 2017 Northrop Grumman Systems Corporation – All Rights Reserved