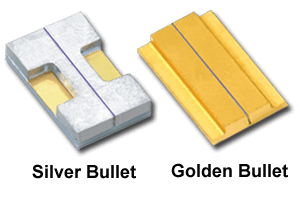

Cutting Edge Optronics (CEO) manufactures laser diode arrays based on two main types of technology, hard solder (CEO Golden Bullets) and soft solder (CEO Silver Bullets). Golden Bullets are state-of-the-art and are built using gold-tin solder and heat sinks that have the same CTE (coefficient of thermal expansion) as the laser diode bar. As a result, arrays built from Golden Bullets are extremely resistant to solder creep and other failure modes that result from thermal expansion and contraction in the array.

Cutting Edge Optronics (CEO) manufactures laser diode arrays based on two main types of technology, hard solder (CEO Golden Bullets) and soft solder (CEO Silver Bullets). Golden Bullets are state-of-the-art and are built using gold-tin solder and heat sinks that have the same CTE (coefficient of thermal expansion) as the laser diode bar. As a result, arrays built from Golden Bullets are extremely resistant to solder creep and other failure modes that result from thermal expansion and contraction in the array.

Silver Bullets are an excellent low-cost option for many laser diode arrays and are built using copper heat sinks and indium solder. CEO has packaged approximately one million laser diode bars in this configuration and they are used throughout the industrial, scientific, and military laser marketplace. Under the right operating conditions, arrays built using Silver Bullets can be expected to provide in excess of 40,000 operating hours.

Which package is right for me?

CEO has done extensive life testing over the past five years to determine the appropriate operating regimes for each of its packages. In general, Golden Bullets (hard solder) are required for applications that involve a high number of thermal cycles. In these applications there is a significant amount of thermal expansion and contraction of the laser diode arrays. In order to maintain the physical integrity of the package, Golden Bullet construction methods are required (hard solder, CTE-matched heat sinks). Golden Bullets have also been shown to have longer lifetimes in applications requiring high per-bar power levels. Some examples of operating conditions requiring Golden Bullets are:

1) Continuous-wave (CW) applications with a high number of on/off power cycles. If the application requires the diode arrays to be turned on and off more than a few times an hour, arrays built from Golden Bullets will provide superior lifetimes.

2) Quasi-CW (QCW) applications with long pulse widths (> 400 µs). Long pulse widths are common in many direct-diode and solid-state laser (SSL) pumping applications. Examples of SSL crystals which are typically pumped in this fashion are Yb:YAG, Er:YAG, Ho:YAG, etc.

3) Any application which includes wide swings in storage and/or operating temperatures (greater than 15 ºC). Examples of this include many military/aerospace applications that are specified to function over MIL-SPEC temperature ranges (-40 ºC to +70 ºC, for example).

4) Any QCW application in which the peak output power per bar is greater than 80 Watts.

5) Any CW application in which the output power per bar is greater than 40 Watts.

Free Engineering Consultation>>

Note that if the application fails to meet any of the above criteria, it is likely that a package based on Silver Bullet technology is the proper solution. For example, Silver Bullet technology is well-proven in CW applications at power levels of less than 35 W/bar. CEO utilizes Silver Bullet technology in many of its gain module and laser products that have become industry standards, in part because of their established records of tens of thousands of hours of reliable operation.